|

FS300

Foundationless Free Standing Jib Cranes

1/8 Ton to 1 Ton

|

|

|

|

Foundationless

Free Standing Jib Cranes is our most versatile

crane. They are perfect to place underneath large bridge

cranes, in open areas where they can serve several work

stations, in outdoor applications such as loading docks, or in

machining and assembly operations where they can be over-

lapped with other jibs to provide staged operation. |

|

|

|

| Our

Advantage: |

|

|

|

| Ease

of Operation |

|

|

|

•

Allows operators to position loads precisely, effortlessly

and efficiently

• Precision tapered roller bearings in top pivot and trunnion

assemblies provide smooth operation and long life

• Full supporting triangular base plate gussets are used (in

lieu of struts) to minimize crane deflection, thus making it

easier to accurately position loads |

|

|

|

| Ease

of Installation |

|

|

|

•

Independent head assembly, installed separately from the

boom for easier installation

• Recessed bearing assembly allows greatly reduced

clearances needed for installation

• Bolted head/boom connection which permits separate

installation and provides maximum lift for the hoist, since

it can be installed very close to the underside of the lower

ceiling obstruction for greater headroom

• Movable bolted trolley stops

• In-head totally enclosed, bottom entry collector assembly

allows the option of easily adding power to the hoist for

360° rotation at the time of or after purchase |

|

Safety |

|

• Head retaining

pin provides the resistance to

accidental upward dislodgement of the head. |

|

|

|

Full

Rated Capacity

• Pre-engineered for use with powered hoists. A

factor of 15% of the jib crane capacity is allowed

for the hoist and trolley weight with an additional

25% of the capacity allowed for impact, thus giving

full rated capacity use of the jib |

|

|

|

|

|

|

|

|

|

What

are the benefits of Foundationless Jib Cranes? |

| Designed

for Performance |

|

|

|

|

Save

Money! |

Our

boxed style head provides benefits from installation

through operation of the jib crane. The design allows for

installation of the head prior to the boom, which reduces

the required installation clearances and allows maximum

hoist lift. |

|

|

Instaling

a poured foundation can be expensive, it can

cost as much or more than the jib crane itself. With

foundationless jib cranes, you eliminate the cost of

pouring a concrete foundation, potentially saving

thousands. |

|

|

|

|

| The

boxed style head also increases stability versus |

|

|

|

common

sleeve-over-

pipe designs. The

result is less de-

flection and

bouncing of the

load, which creates

a safer application

with reduced risk

of product damage. |

|

|

|

Save

Time!

Poured foundations can take up to a week to cure

before you can install the jib. Now there's no waiting.

Machine downtime can be reduced by not needing

to shut down machines to bringe in special equipment

to install a foundation. |

|

|

|

|

|

|

|

|

Location

Control

It's easy to relocate a jib where there's no poured

foundation. That means more flexibility in choosing

initial jib location. You can place it closer to machines

or other obstructions, because there is no need to a

large square foot area for a concrete pour. If your

operational flow changes, you can easily relocate the

jib fit your changing needs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STANDARD

BOOM DATA |

Boom

Height (W) |

Beam Size |

Flange

Width (in) |

|

6" |

W6@12#/ft. |

4" |

|

8" |

W8@18.4#/ft. |

5-1/4" |

|

10" |

W10@26#/ft. |

5-3/4" |

|

12" |

W12@35#/ft. |

6-1/2" |

|

|

|

|

|

Capacity

|

Span

|

Foundation

size

(sq. ft.)

|

|

1/8

ton

|

4'

- 17'

|

7'

x 7'

|

|

18'

- 20'

|

8'

x 8'

|

|

1/4

ton

|

4'

- 10'

|

7'

x 7'

|

|

11'

- 14'

|

8'

x 8'

|

|

15'

- 20'

|

9'

x 9'

|

|

1/2

ton

|

4'

- 6'

|

7'

x 7'

|

|

7'

- 9'

|

8'

x 8'

|

|

10'

- 12'

|

9'

x 9'

|

|

13'

- 15'

|

10'

x 10'

|

|

16'

- 20'

|

11'

x 11'

|

|

1

ton

|

4'

6'

|

8'

x 8'

|

|

7'

|

9'

x 9'

|

|

8'

- 10'

|

10'

x 10'

|

|

11'

- 12'

|

11'

x 11'

|

|

13'

- 16'

|

12'

x 12'

|

|

| Chart

1B. Boom data. |

|

|

|

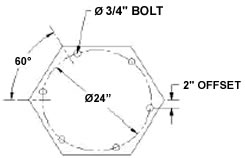

Diagram

2H. 6 bolt base bolt pattern |

|

|

|

|

|

|

|

|

|

PIPE

SIZE

|

DIMENSIONS

|

|

E

|

G1

|

G2

|

J

|

K

|

H1

|

H2

|

|

8

|

10

|

20

|

20-3/8

|

10

|

46-3/4

|

4

|

|

12

|

8-1/2

|

20

|

12-7/8

|

12-1/2

|

71-3/4

|

6

|

|

|

|

|

|

|

| Chart

2H. Crane dimensions for Foundationless Jibs with hexagonal baseplates. |

|

|

|

|

|

|

|

|

|

Chart

2J. Distance of jib from cracks,

seams, walls. |

|

|

|

|

|

|

| STANDARD

BOOM DATA |

Boom

Height (W) |

Beam Size |

Flange

Width (in) |

|

6" |

W6@12#/ft. |

4" |

|

8" |

W8@18.4#/ft. |

5-1/4" |

|

10" |

W10@26#/ft. |

5-3/4" |

|

12" |

W12@35#/ft. |

6-1/2" |

|

|

|

|

|

|

Capacity

|

Span

|

Foundation

size

(sq. ft.)

|

|

1/8

ton

|

4'

- 17'

|

7'

x 7'

|

|

18'

- 20'

|

8'

x 8'

|

|

1/4

ton

|

4'

- 10'

|

7'

x 7'

|

|

11'

- 14'

|

8'

x 8'

|

|

15'

- 20'

|

9'

x 9'

|

|

1/2

ton

|

4'

- 6'

|

7'

x 7'

|

|

7'

- 9'

|

8'

x 8'

|

|

10'

- 12'

|

9'

x 9'

|

|

13'

- 15'

|

10'

x 10'

|

|

16'

- 20'

|

11'

x 11'

|

|

1

ton

|

4'

6'

|

8'

x 8'

|

|

7'

|

9'

x 9'

|

|

8'

- 10'

|

10'

x 10'

|

|

11'

- 12'

|

11'

x 11'

|

|

13'

- 16'

|

12'

x 12'

|

|

| Chart

1B. Boom data. |

|

|

|

|

|

|

|

|

|

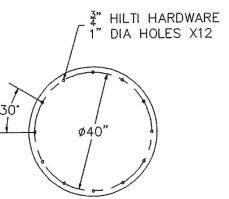

Diagram

2J. 44" dia. 12 bolt base bolt

pattern. |

|

|

|

|

|

|

|

|

PIPE

SIZE

|

DIMENSIONS

|

|

E

|

G1

|

G2

|

J

|

K

|

H1

|

H2

|

|

12

|

15-7/8

|

20

|

12-7/8

|

12-1/2

|

71-3/4

|

6

|

|

14

|

15

|

22

|

15-3/8

|

15

|

72

|

8

|

|

|

| Chart

2I. Crane dimensions for Foundationless Jibs with round baseplates. |

|

|

|

|

|

|

|

|

|

|

|

Chart

2J. Distance of jib from cracks,

seams, walls. |